From Ketchup to Concrete: The Surprising Science of Fluid Suspensions

2025-04-07

Author: Siti

Introduction

Have you ever wondered why ketchup seems to defy gravity when you squeeze the bottle, or how concrete retains its fluidity before setting? The science behind suspensions—mixtures where solid particles are dispersed in a liquid—holds the key to understanding these everyday phenomena. Materials scientists categorize suspensions as liquids containing tiny, insoluble solid particles evenly distributed within them.

Depending on the concentration and interactions between these particles, suspensions can exhibit unexpected behaviors, particularly when forced.

The Behavior of Non-Newtonian Fluids

One fascinating aspect is the behavior of non-Newtonian fluids, which become thicker when a strong force is applied. In other words, under stress, these fluids can momentarily act like solids. This thickening occurs because the particles in the suspension must rearrange themselves when the fluid is deformed.

The ideal movement of particles is to roll past each other; however, when they encounter constraints—like becoming jammed—they must slide against one another, which demands significantly more energy. This results in the liquid feeling much more viscous.

Research Advances at ETH Zurich

To enhance understanding and functionality of these suspensions, researchers need to delve into the forces at play between particles. Recently, a team of materials researchers at ETH Zurich, led by Professor Lucio Isa, made significant strides in this area by measuring the frictional forces exerted between individual particles that are as small as 12 micrometers in diameter.

Their groundbreaking work has been featured in the prestigious *Proceedings of the National Academy of Sciences*.

Methodology

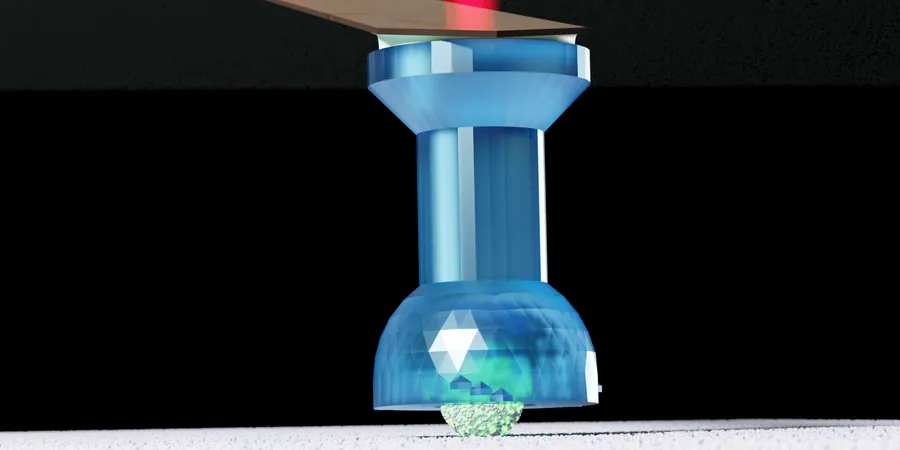

Employing a sophisticated atomic force microscope, the researchers meticulously crafted a micro holder to isolate and manipulate a single spherical particle. By sliding this particle across a surface resembling its characteristics, they simulated interactions between two particles and measured the forces involved.

The challenge was formidable; developing a working holder to trap such small particles required numerous iterations—up to 50 prototypes—before achieving success.

Findings

The study revealed intriguing behaviors among differently structured particles. For instance, those with smooth, slippery surfaces slid past one another irrespective of pressure, while rough or sticky particles engaged like gears, rolling with minimal resistance.

Furthermore, when measuring sliding friction, the researchers discovered it was significantly higher than rolling friction, underpinning the rapid thickening observed in suspensions.

Implications for Industry

Why is this knowledge so valuable? The researchers managed to derive coefficients for both rolling and sliding friction from their measurements, crucial data that can be integrated into computer models simulating dense particle suspensions.

This has profound implications for various industries, like construction and microelectronics. For example, electronics manufacturers rely on dense suspensions with conductive particles for soldering circuit board components. Troubles arise when pressure builds in dispensing nozzles, causing sudden thickening that can lead to clogs.

Conclusion

Professor Isa emphasizes the importance of understanding microscopic particle behavior: "In order to avoid unexpected issues and refine suspensions in such applications, we need to know precisely how particles interact on a microscale and the forces that come into play."

This research not only enhances our understanding of commonplace materials but also holds the potential to revolutionize how various industries approach the design and optimization of fluid suspensions. Whether it's improving the flow characteristics of concrete or enhancing electronic soldering processes, the implications are vast and significant. So the next time you pour ketchup or see concrete being laid down, remember the complex science at work beneath the surface!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)