Building on the Moon: How NASA and ICON Are Revolutionizing Lunar Construction with 3D Printing

2025-05-19

Author: Rajesh

NASA and ICON: Pioneers of Lunar Construction

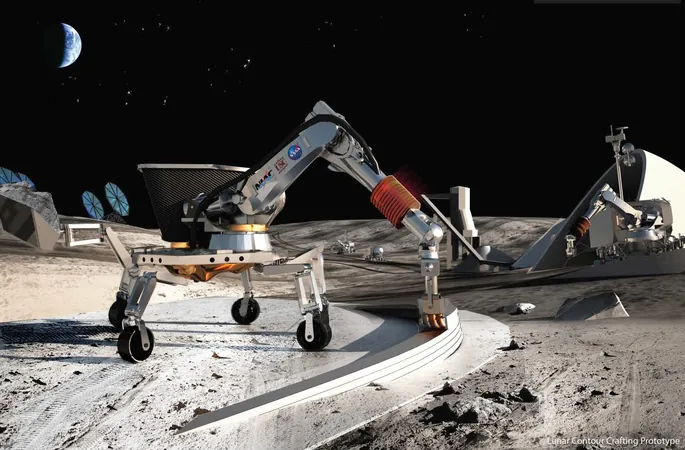

In an extraordinary leap for space exploration, NASA and Texas-based construction innovator ICON are transforming the future of lunar infrastructure. Their collaboration focuses on harnessing advanced 3D printing technology to fabricate habitats, landing pads, and roads directly on the Moon and Mars by using local materials like lunar regolith.

Testing Moon Soil in Space Conditions

This partnership, which evolved from NASA’s 3D Printed Habitat Challenge, recently reached an exciting milestone. In February 2025, ICON launched a groundbreaking experiment named Duneflow aboard a Blue Origin reusable rocket, simulating lunar gravity for two minutes. This critical test aimed to analyze how Moon soil behaves under low-gravity conditions, drawing insightful comparisons with real lunar samples gathered during Apollo missions.

The Game-Changing Olympus Construction System

At the heart of this initiative is ICON's cutting-edge construction platform, Olympus. Unlike traditional methods that depend on Earth-sourced materials, Olympus employs a revolutionary technique known as Laser Vitreous Multi-material Transformation. By utilizing a powerful laser to melt local soils into robust, ceramic-like materials, Olympus creates strong infrastructure right where it’s needed, effectively slashing the costs and logistical challenges of transporting building materials from Earth.

Cost-Effective Solutions for Space Exploration

Printing construction materials on-site is not just innovative; it’s essential. Each kilogram launched into space dramatically increases mission expenses, making in-situ resource utilization (ISRU) a crucial strategy for future exploration. The ability to fabricate roads, landing pads, and even crew habitats using local regolith could redefine how we approach lunar and Martian missions.

Tracking ICON's Earthly Successes

ICON has already made waves back on Earth with its Vulcan construction system, which has successfully 3D printed full-size homes across the United States. These terrestrial projects provide invaluable insights that are now being adapted for extraterrestrial applications, with NASA backing ICON through various initiatives to refine their technology for space.

Building Autonomously for Space Missions

ICON’s innovative efforts align perfectly with NASA's broader research initiatives. Programs like the Moon to Mars Planetary Autonomous Construction Technology (MMPACT) initiative are designed to create autonomous systems capable of building necessary infrastructures without human oversight, particularly vital for early missions when astronauts may not be present.

Ongoing Innovations and Future Missions

Building on prior research funded by NASA’s Innovative Advanced Concepts (NIAC) program, ICON’s Olympus embodies decades of research into planetary construction. It integrates advanced techniques learned from pioneers like Behrokh Khoshnevis, who previously developed large-scale 3D printing concepts.

Mars Dune Alpha: Testing on Earth for Future Missions

Further showcasing these advancements, ICON constructed Mars Dune Alpha, a 1,700-square-foot simulated habitat at NASA’s Johnson Space Center. This unique living space is part of the CHAPEA project, where volunteer crews experience life in a Mars-like environment for an entire year, testing how 3D-printed habitats can sustain long-term missions.

A New Era in Space Construction Awaits

The collaboration between NASA and ICON stands at the forefront of integrating 3D printing into space construction. As they enter a critical testing phase, the dream of establishing real structures on the Moon and Mars is within reach, paving the way for humanity's next giant leap into the cosmos.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)