Breakthrough in Laser Technology: Room-Temperature Lasing with Photonic-Crystal Magic

2025-07-12

Author: Wei

Revolutionizing Laser Design at Room Temperature

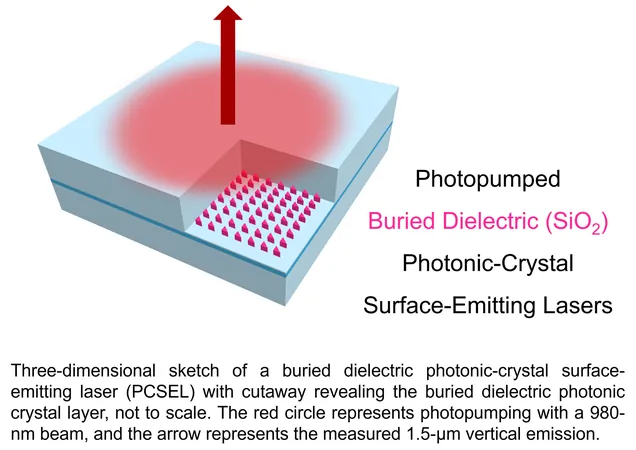

In an exciting milestone for laser technology, researchers from The Grainger College of Engineering at the University of Illinois Urbana-Champaign have achieved photopumped lasing from a buried dielectric photonic-crystal surface-emitting laser, all at room temperature and emitting in an eye-safe wavelength. Their groundbreaking findings, highlighted in the IEEE Photonics Journal, promise to pave the way for advanced laser applications, especially in defense.

The Legacy of VCSELs Takes a Giant Leap

For years, the lab led by Professor Kent Choquette has been at the forefront of vertical-cavity surface-emitting lasers (VCSELs), the technology behind everyday gadgets like smartphones, barcode scanners, and even automotive devices. But the game changed in early 2020 when Choquette's team took notice of innovative research from Japan, unveiling the potential of a new laser type: photonic-crystal surface-emitting lasers (PCSELs).

PCSELs: A New Frontier in Laser Efficiency

PCSELs represent a thrilling evolution in semiconductor lasers. By integrating a photonic crystal layer, they deliver exceptionally high brightness and precise beam profiles, making them ideal for critical defense technologies such as LiDAR—essential for battlefield mapping and navigation. Supported by the Air Force Research Laboratory, Choquette's team set out to explore the transformative capabilities of this emerging technology.

A Vision for the Future of PCSELs

"We anticipate that PCSELs will play an essential role moving forward," stated Erin Raftery, a graduate student and lead author of the study. "They haven’t yet achieved their full industrial potential, and we're committed to advancing this field."

Innovative Solutions to Manufacturing Challenges

Traditionally, PCSELs use air holes in their structure, which can collapse during the regrowth of semiconductor material, leading to compromised quality. To overcome this issue, the Illinois team ingeniously replaced these air gaps with solid dielectric materials. By introducing silicon dioxide into the semiconductor structure, they successfully demonstrated a new design featuring embedded dielectric elements, achieving a significant innovation.

Achieving the Impossible with Semiconductors

"When we first attempted to regrow the dielectric, we faced uncertainty about its feasibility," Raftery reflected. "Maintaining a pure crystal structure during growth is complex, especially with amorphous materials. Yet, we managed to seamlessly grow around the dielectric material, achieving a notable breakthrough."

A Bright Future Awaits: Applications and Innovations

Experts predict that within the next two decades, these enhanced lasers will revolutionize various sectors, from autonomous vehicles to precision laser cutting and welding. The Illinois engineering team is already working on refining their design to facilitate easier integration with power sources, bringing the dream of practical, high-performance PCSELs closer to reality.

Collaboration is Key to Success

Professor Choquette emphasized the importance of collaboration in this success: "The expertise brought by Erin and the Minjoo Larry Lee group, alongside the resources at Wright-Patterson Air Force Base, were critical in achieving these results. We eagerly await the operational future of diode PCSELs."

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)