Breakthrough in Hydrogen Production: Lithuanian Scientists Tackle Tar Issue in Waste Gasification!

2025-03-19

Author: Arjun

Breakthrough in Hydrogen Production: Lithuanian Scientists Tackle Tar Issue in Waste Gasification!

As the world urgently seeks more sustainable energy options, researchers from Lithuania are making waves with an innovative approach to hydrogen production. This groundbreaking technology not only converts waste into highly valuable hydrogen but also addresses a critical problem in conventional gasification processes—tar contamination. This advancement signals a major leap forward in the quest for cleaner energy solutions.

Hydrogen's role in facilitating the transition to environmentally friendly energy sources cannot be overstated. However, traditional gasification techniques often yield synthesis gases with only minimal hydrogen content due to the presence of tar, which significantly hinders hydrogen purity and usability as a clean fuel.

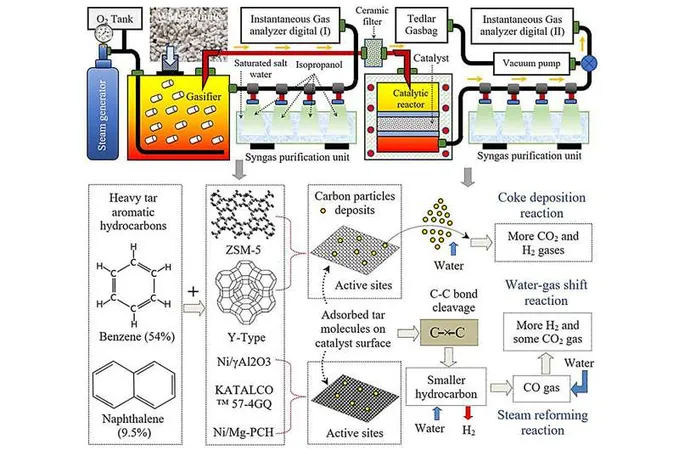

To overcome these barriers, a research team from the Kaunas University of Technology (KTU) and the Lithuanian Energy Institute (LEI) has unveiled a two-step conversion system featuring an updraft gasifier paired with a catalytic reforming reactor. Their findings have been published in the prestigious journal Energy.

Revolutionizing Hydrogen Production

The innovative process begins with gasification, where waste is subjected to heat in a carefully controlled environment of steam and oxygen, resulting in a syngas—a synthetic gas product. However, the generation of tar can lead to decreased efficiency, equipment corrosion, and hinder key chemical reactions crucial to maximizing hydrogen extraction.

Dr. Samy Yousef, the chief researcher at KTU, emphasized the promise of gasification for environmental sustainability: “This emerging technology is capable of converting various waste types into syngas while minimizing harmful by-products.”

The breakthrough lies in the post-gasification treatment, where the syngas is channeled through a catalytic reforming reactor. This step effectively dismantles tar into simpler molecules, enabling higher hydrogen yield—up to 60% volumetrically—transforming syngas into a cleaner fuel source.

According to Dr. Yousef, the choice of catalysts is integral to the process. Extensive tests on various commercial and lab-developed catalysts led them to discover that KATALCO 57-4GQ stood out for its exceptional surface area and durability, ultimately proving most effective in breaking down tar.

Versatility and Efficiency Redefined

Unlike traditional gasification methods requiring high-energy plasma systems, this new two-step process operates under atmospheric pressure. This not only cuts down infrastructure costs but also greatly enhances operational safety.

When contrasted with the prevailing method of hydrogen production—steam methane reforming (SMR)—this innovative approach offers distinct advantages. SMR relies on natural gas, a fossil fuel, which results in significant carbon dioxide emissions. Dr. Yousef emphasizes the eco-friendliness of their method: “Our approach utilizes waste as a renewable resource, unlike SMR’s reliance on non-renewable sources.”

Although the initial studies centered on medical waste, the capabilities of this technology are boundless. It can be applied to a wide array of organic materials and industrial waste, including plastics, textiles, and biomass. Of note, effective pre-treatment of these materials is essential for optimal processing.

As the research progresses, KTU’s findings indicate the technology has achieved a Technology Readiness Level (TRL) of 5, a significant milestone on a globally recognized scale for evaluating technology maturity. Dr. Yousef explains, “Being at TRL5 signifies our technology has undergone extensive testing, simulating real-world industrial scenarios, and is on the brink of full-scale deployment.”

With further research and refinements, the road to commercializing sustainable hydrogen production seems increasingly feasible. This development could herald a new era in renewable energy, making clean hydrogen fuel a reality and propelling society toward long-term energy sustainability.

Stay tuned as the hydrogen market evolves—follow the latest updates at Hydrogen Central!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)