Breakthrough Discovery: Simple Temperature Control Unlocks Efficient Production of Single-Domain Ferroelectric Thin Films!

2025-03-10

Author: Daniel

Introduction

In a groundbreaking study, a research team led by Prof. Hu Weijin at the Institute of Metal Research (IMR) of the Chinese Academy of Sciences has unveiled an innovative method for producing single-domain ferroelectric thin films through the uncomplicated manipulation of growth temperatures. This discovery, highlighted in the prestigious journal Advanced Functional Materials, opens up new avenues in the realm of ferroelectric device engineering, potentially revolutionizing their performance.

Traditional Challenges

Traditionally, ferroelectric materials tend to form polydomain structures, a defensive mechanism to minimize electrostatic energy. However, achieving single-domain thin films, which are preferable for many applications, often requires intricate techniques that can limit scalability. The IMR team's work showcases a much simpler alternative that could lead to significant improvements in ferroelectric device functionality.

Experimental Methodology

In their experiments, the researchers utilized barium titanate (BaTiO3 or BTO) ferroelectric films layered onto La0.67Sr0.33MnO3 (LSMO) metal substrates, applying pulsed laser deposition at elevated temperatures ranging from 700°C to a staggering 850°C. Their results indicated a remarkable transformation; when the LSMO substrate was grown above 800°C, the resultant BTO films achieved a single-domain state, dramatically enhancing their properties.

Mechanism Behind the Discovery

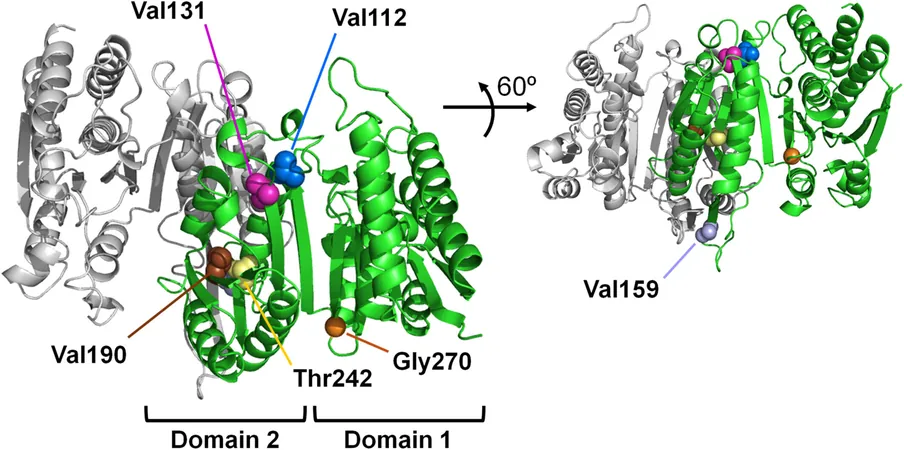

The magic seems to happen at the interfacial level, where strontium ions migrate towards the interface during the elevated temperature process, forming a positively charged surface. This reconfiguration aligns the electric polarization uniformly throughout the film, a finding that could have profound effects on device integration.

Simplifying Production

"This approach is streamlined compared to more complex methods like atomic layer engineering, which often involves meticulous surface treatments and rigorous growth control," stated Hu. "Our findings not only simplify the process but hold promise for the large-scale manufacturing of single-domain films that exceed the current dimensions of 5 mm × 5 mm. Techniques such as spin coating could facilitate its industrial scalability."

Implications and Future Applications

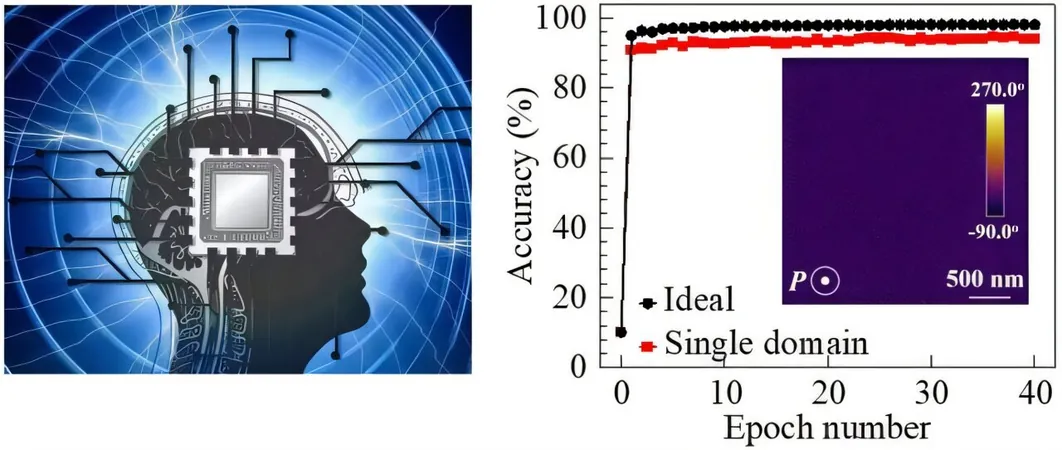

The implications of this research extend far beyond mere production efficiency. The advent of high-performance single-domain ferroelectric films could drastically uplift the capabilities of ferroelectric synaptic devices utilized in neuromorphic computing—an area mimicking the neural architectures of the human brain. Additionally, this innovation can also play a significant role in advancing optoelectronics and catalysis, providing a versatile tool for varied technological applications.

Conclusion

In a world that thrives on efficiency and scalability, this novel approach could herald a new era in ferroelectric material technology, paving the way for smarter, more efficient devices that redefine what's possible in electronics. Stay tuned as this story unfolds!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)