Raspberry Pi's Ingenious Soldering Shift Cuts Returns by 50%!

2025-04-30

Author: Ming

Revolutionizing Soldering for Better Reliability

Through-hole soldering can be a real headache for DIY enthusiasts armed with soldering irons and endless supplies. In a surprising turn of events, even a tech giant like Raspberry Pi faced challenges with this traditional method, despite producing over 60 million devices.

The Mixing of Technologies

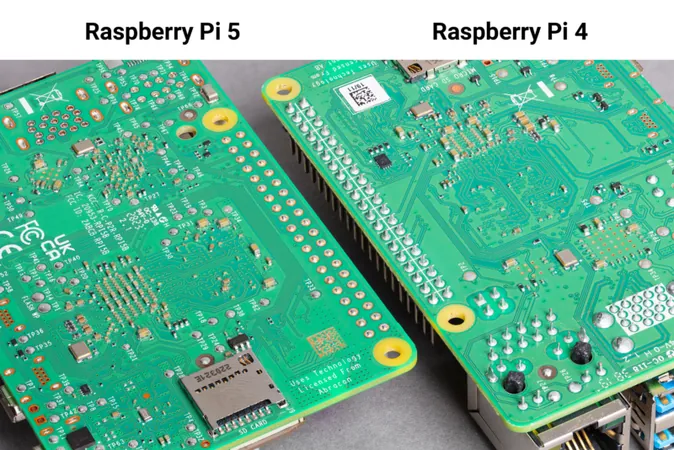

Raspberry Pi boards are a blend of surface-mount devices (SMDs) and through-hole components. While SMDs allow for densely packed tiny chips and resistors attached via tiny pins and solder balls, larger components still require the reliable strength of through-hole soldering, especially when they endure a bit of rough handling.

The iconic Raspberry Pi board features a 40-pin GPIO header, among other ports like Ethernet and USB, all requiring solid solder links. Initially, these components were added manually, later transitioning to robotic insertion before undergoing a secondary wave soldering process.

A Game-Changing Technique: Intrusive Reflow Soldering

Fast forward to the present, where Raspberry Pi has dramatically upgraded their production process in collaboration with their UK manufacturing partner, Sony. By embracing the intrusive reflow soldering technique, the company can now solder tiny SMDs and larger components simultaneously.

This innovative process involves placing solder paste on both SMD pads and through-hole pins. When the components are pushed into the paste, the entire assembly is heated in a reflow oven, allowing the solder to melt, secure connections, and form lasting joints—all in a single step.

Impressive Results: Cutting Returns and Carbon Footprint

The results? A staggering 50% reduction in product returns and a 15% boost in production efficiency! By eliminating the separate soldering phase, Raspberry Pi not only improved their assembly line but also reduced carbon emissions by 43 tonnes annually.

A Remarkable Milestone for Hobbyists

When we reached out to Raspberry Pi for clarification on those impressive return statistics, it sparked curiosity about their future product lines. Regardless, this evolution in their soldering process reveals significant benefits, leaving many in the DIY community envious of the advanced techniques that now set the standard for reliability and efficiency.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)