Unraveling the Mystery of Suspensions: From Ketchup to Concrete, How Rolling Particles Enhance Fluid Dynamics

2025-04-07

Author: Liam

Introduction

In our daily lives and across various industries, suspensions play a crucial role. These are liquids containing tiny insoluble solid particles uniformly dispersed throughout them—think ketchup, paint, and concrete. Interestingly, under certain conditions, these suspensions can exhibit peculiar behaviors that challenge our conventional understanding of fluidity.

Non-Newtonian Fluids and Their Behaviors

One compelling characteristic of these so-called non-Newtonian fluids is that they can suddenly thicken and behave like solids when a significant force is applied. This strange phenomenon occurs because the particles within the suspension must adjust their arrangement when the mixture is deformed. When this rearrangement is possible, particles can roll past one another, allowing the suspension to flow. However, when the arrangement becomes jumbled, sliding takes over—an action that requires considerably more force, thereby increasing the mixture's viscosity.

Research Breakthroughs at ETH Zurich

Understanding the forces at play on a microscopic level is essential for optimizing the flow characteristics of these suspensions. Researchers from ETH Zurich, led by Lucio Isa, Professor of Interfaces and Soft Matter, have made significant strides in this area. Their groundbreaking study, published in the *Proceedings of the National Academy of Sciences*, sheds light on the frictional forces between minute particles, which are often just a few micrometers in diameter.

Innovative Measurement Techniques

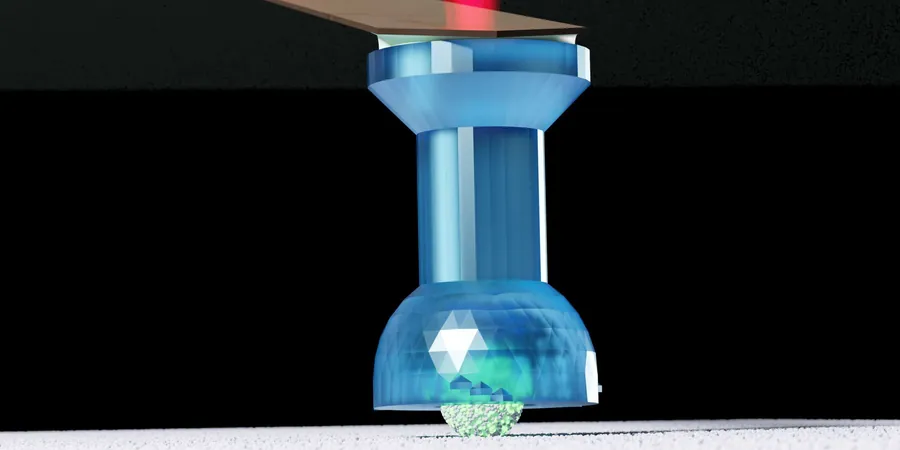

Using an atomic force microscope, PhD student Simon Scherrer developed a specialized microscopically small holder designed to capture individual spherical particles. This setup allows researchers to simulate the interaction between two particles rolling against each other over a flat surface, effectively measuring the tiny forces involved in the process.

Challenges in Microscopic Research

The challenge of creating effective measurement techniques for these minuscule particles, which can be as small as 12 micrometers—equivalent to 12 millionths of a meter—was monumental. Scherrer humorously noted, “I must have developed 50 versions until I found one that met the requirements,” reflecting the painstaking effort involved in perfecting their measurement apparatus.

Impact of Particle Surface Characteristics

Different particle types were manufactured to investigate how surface characteristics affect suspension behavior. Notably, smooth or slippery particles demonstrated a tendency to slide past one another with ease, irrespective of the pressure applied. In contrast, rough or sticky particles interacted much more like gearwheels, rolling against each other with minimal resistance. This fundamental difference explains the significant gap between rolling and sliding friction—the latter being far more intense, contributing to that dramatic thickening effect often observed in suspensions.

Practical Applications and Implications

The data obtained from this research holds immense practical value. By calculating the coefficients for rolling and sliding friction of individual particles, scientists can input these figures into computer simulations to accurately model the behavior of high-density suspensions. This knowledge is invaluable, offering insights that could revolutionize industries reliant on suspension characteristics for their products.

Industry Benefits and Innovations

Industries such as concrete manufacturing and microelectronics stand to benefit immensely from these discoveries. For instance, microelectronics firms use dense suspensions containing metallic, conductive particles for tasks like soldering components onto circuit boards. If pressure is mismanaged during the process, the solder paste can inadvertently thicken and block narrow nozzles—a hiccup that can be avoided with a deeper understanding of particle interactions.

Conclusion

Isa emphasizes the importance of this research: “In order to prevent these behaviors and optimize such suspensions, we need precise knowledge of how particles behave on a microscale and the forces that arise in these interactions.” As scientific advancements continue to unravel the complexities of suspensions, the potential for innovation across numerous fields is limited only by our imagination.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)