Revolutionizing Plant-Based Meats: Can AI and Mechanical Testing Create the Ultimate Meat Alternative?

2024-11-15

Author: Liam

Introduction

In our ongoing quest to reduce climate change and save on resources, the shift from animal protein to plant-based diets has gained momentum. However, convincing devoted meat lovers to embrace alternatives remains a challenging hurdle. Enter a groundbreaking study from Stanford University, where engineers are employing innovative mechanical testing combined with machine learning to enhance the texture of plant-based meats, potentially transforming the culinary landscape for even the staunchest carnivores.

Mechanical Testing and Machine Learning

Published in the journal *npj Science of Food*, the Stanford research team illustrates how mechanical testing and sophisticated algorithms can analyze food texture with remarkable accuracy, akin to how human taste testers perceive it. This revolutionary approach not only aims to speed up the development of plant-based products but has also revealed that some current offerings are already impressively mimicking the textures of traditional meats.

Advancements in Plant-Based Textures

"Today's plant-based products have made significant strides, achieving a texture that closely resembles the spectrum of textures found in animal meats," states Ellen Kuhl, a professor of mechanical engineering and the study's senior author. This marks a notable advancement since the days when tofu was often the only alternative on the market.

Environmental Impact

The environmental cost of industrial animal agriculture is staggering, contributing to climate change, pollution, habitat destruction, and antibiotic resistance. By replacing animal proteins with plant ones, we could significantly lessen this burden. Research shows that plant-based meats commonly have about half the environmental impact of their animal-derived counterparts.

Consumer Reluctance

Despite this, a significant portion of meat consumers remain hesitant to switch—recent surveys indicate that only one in three Americans expressed a strong willingness to purchase plant-based alternatives. "The affinity for meat is deep-seated," remarked Skyler St. Pierre, a Ph.D. student in mechanical engineering and lead author of the study. "To persuade passionate meat eaters to explore these alternatives, ensuring our plant-based products closely mimic the real thing is essential."

Bridging the Gap in Testing

To accurately replicate animal textures, food scientists examine the composition of plant-based meats. Traditional testing methods, unfortunately, lack standardization, making it hard for producers to innovate collaboratively. This gap is what the Stanford team set out to bridge.

Research Origins and Methods

The research's inception stems from a class project where St. Pierre ingeniously utilized hot dogs and tofu for mechanical tests. Over the summer of 2023, the team engaged undergraduates in a hands-on investigation into how these foods respond to mechanical stress.

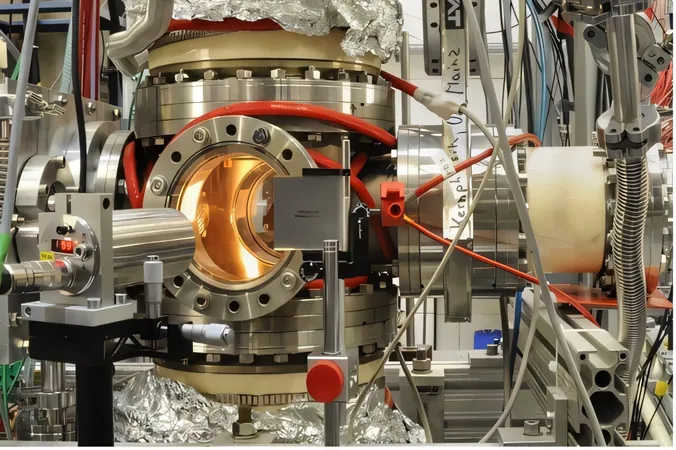

Results of Mechanical Testing

Through a pioneering technique, the Stanford researchers tested eight products, including both animal and plant-based hot dogs and sausages, as well as turkey variants and firm tofu. They used specialized equipment to simulate the forces acting on food during chewing, taking a closer look at how each sample held up under various mechanical strains.

Machine Learning Integration

By leveraging machine learning algorithms, the team processed their findings to produce equations that accurately describe the food's textural properties. They further validated these theories with a taste test, gathering responses on various factors such as softness, chewiness, and overall meat-like quality.

Impressive Discoveries

What they discovered was nothing short of impressive: the plant-based hot dogs and sausages showcased mechanical properties strikingly similar to their meat counterparts, while the plant-based turkey was found to be stiffer than the animal turkey. Notably, human testers rated the stiffness of the plant-based hot dogs and sausages in alignment with the mechanical data.

Outcomes and Future Directions

"This incredible correlation between human and machine rankings signifies a leap forward in food texture testing," highlights Kuhl. "This paves the way for a reliable, reproducible method that could significantly enhance the quality of plant-based products."

Potential for AI in Recipe Development

The implications of this research could revolutionize the way companies develop these products. The authors suggest a future where generative artificial intelligence can create scientifically sound recipes for plant-based meats tailored to meet specific texture preferences, expediting the innovation process.

Data Sharing for Innovation

However, successful AI integration in recipe development hinges on the availability of substantial datasets. Committed to fostering innovation in the field, the Stanford team has made their findings publicly accessible online. "For too long, data sharing has been a significant barrier to progress," St. Pierre mentions, emphasizing the collaborative spirit essential for creating advanced meat alternatives.

Looking Ahead

Looking ahead, the team is poised to expand their testing regiment, building a comprehensive database of vegetarian and meat mock deli slices. With assistance from new faculty member Vayu Hill-Maini at Stanford, they also plan to explore engineered fungi as a potential ingredient in meat substitutes. "We encourage anyone with novel plant-based or artificial meat products to come forward," Kuhl assures. "We’d love to evaluate how they measure up!"

Conclusion

In an age where eco-consciousness is at the forefront of consumer choices, the efforts of these innovators may well lead to plant-based products that truly satisfy the taste buds—and perhaps even convert the most dedicated meat enthusiasts.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)