Revolutionary Pretreatment Techniques Propel Second-Gen Biofuels from Oilcane Toward Commercial Success

2025-09-04

Author: Jacob

Unlocking Biofuels: A Game-Changer in Energy Production

In an exciting leap forward for renewable energy, a collaboration of leading Bioenergy Research Centers (BRCs) is paving the way for the commercialization of second-generation biofuels derived from oilcane, a high-oil variant of sugarcane. This endeavor, spearheaded by the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI), is crucial as society seeks sustainable alternatives to traditional fuels.

From First-Gen to Second-Gen: A Shift in Biofuel Production

Traditionally, sugarcane was the main feedstock for bioethanol production, classifying it as a "first-generation" biofuel sourced from food crops. This process involves crushing sugarcane stalks for juice extraction, with the fibrous leftovers, known as lignocellulose, usually burned as waste. However, the focus is shifting towards second-generation biofuels, which utilize non-food biomass like lignocellulose, offering a promising solution that does not interfere with food supplies.

Tackling Challenges in Lignocellulose Utilization

While the potential for lignocellulose-derived biofuels is significant, the material poses unique challenges. Its complex structure makes it tough to break down cellulose and hemicellulose into sugars essential for biofuel production. To harness these sugars, efficient pretreatment methods are necessary, yet commercial adoption of these processes remains limited.

Innovative Collaboration Yields Promising Results

A recent inter-BRC study published in Sustainable Energy & Fuels sheds light on various pretreatment methods applied to oilcane lignocellulose. Researchers from CABBI, the Joint BioEnergy Institute (JBEI), and the Great Lakes Bioenergy Research Center (GLBRC) conducted a thorough comparison, evaluating lipid recovery, sugar yield, and ethanol output. This pioneering study is the first of its kind focusing on oilcane.

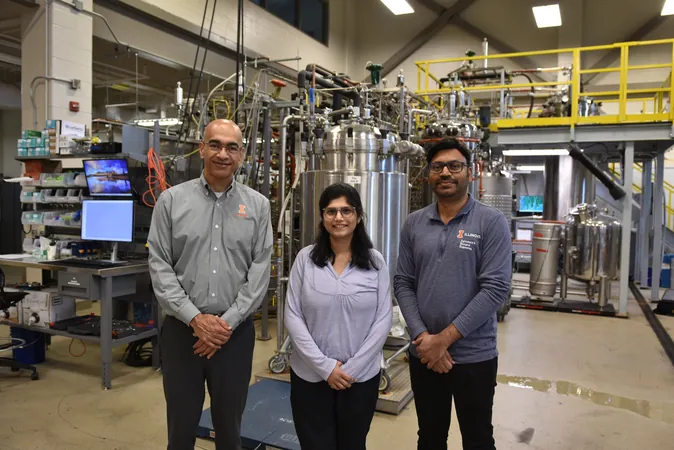

CABBI's Vijay Singh emphasized the significance of this research: "We are assessing the processing of CABBI crops on an industrial scale, vital for advancing the commercial viability of biofuel production from these innovative crops."

Hydrothermal Pretreatment: A Path Forward

Among the findings, researchers unveiled the effectiveness of a hydrothermal pretreatment method, which utilizes hot water or saturated steam to decompose dry plant matter, setting the stage for successful bioprocessing. This method only demands basic ingredients—hot water, enzymes, urea, and specially designed microbes—making it a strong candidate for future commercialization.

Exploring Additional Techniques

Beyond hydrothermal methods, the study also examined ammonia pretreatment by GLBRC and ionic liquid pretreatment by JBEI. All techniques demonstrated industrial viability, a significant milestone in the pursuit of second-generation biofuels.

Economic Impact and Future Prospects

Lead author Narendra Naik Deshavath remarked on the exciting potential of ammonia, hydrothermal, and ionic liquid-based pretreatment methods. The capability to achieve commercially viable ethanol output without requiring extensive post-pretreatment processing presents a transformative opportunity for the biofuel sector.

Utilizing agricultural byproducts like oilcane lignocellulose for biofuel production not only promises energy security for the U.S. but also fosters economic growth. The robust pretreatment techniques explored by CABBI, JBEI, and GLBRC pave the way for efficient fuel production at commercial scales, crucial for fulfilling transportation demands while reducing reliance on foreign oil.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)