Revolutionary New Coating Developed at U of T Could Replace Toxic Non-Stick Substances

2025-07-29

Author: Liam

A Groundbreaking Alternative to Toxic Coatings

Researchers at the University of Toronto have unveiled a revolutionary new material that could serve as a safer alternative to the harmful non-stick chemicals traditionally used in cookware and various other applications.

Combating Health Hazards of PFAS

This innovative substance boasts the ability to repel both water and grease, rivaling the effectiveness of conventional non-stick coatings. Crucially, it contains significantly lower levels of per- and polyfluoroalkyl substances (PFAS)—chemicals associated with severe environmental and health hazards.

Technology at Work in the DREAM Lab

The breakthrough emerged from the Durable Repellent Engineered Advanced Materials (DREAM) lab, led by Kevin Golovin, an associate professor in the Faculty of Applied Science & Engineering. Their recent findings were published in the prestigious journal Nature Communications.

The Quest for Effective Alternatives

"For years, researchers have been striving to identify safer substitutes for PFAS," Golovin notes. "The challenge lay in creating a material that can effectively repel both oil and water, matching the performance of PFAS, which has long posed a barrier for scientists."

History of Non-Stick Chemicals and Their Dangers

Since its introduction in the late 1930s, Teflon—also known as polytetrafluoroethylene (PTFE)—has been lauded for its impressive water and grease-repellent properties. However, the same chemical bonds that grant it durability also lead to its classification as 'forever chemicals,' resisting natural breakdown and accumulating in our environment.

Health Risks Linked to PFAS

The danger of PFAS is well-documented, with research revealing links to cancers, birth defects, and other serious health concerns. These chemicals can build up in organisms, increasing toxicity levels as they ascend the food chain.

Meet the Safer Alternative: PDMS

The U of T team has been focusing on polydimethylsiloxane (PDMS), commonly marketed as silicone. Renowned for its biocompatibility—making it suitable for medical devices—PDMS has now been enhanced to offer performance on par with PFAS.

A Cutting-Edge Technique: Nanoscale Fletching

PhD student Samuel Au has pioneered a novel method called nanoscale fletching, which involves bonding short chains of PDMS to a base material. This process enhances its ability to repel oils significantly.

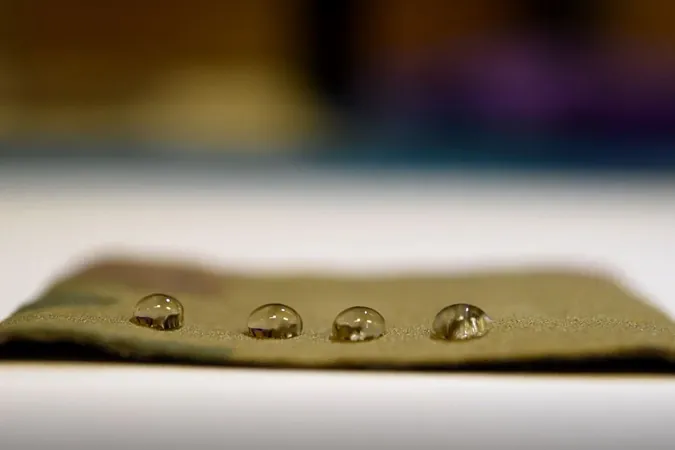

Testing Waters: High Performance Coating

To fuel their claims, the team coated fabric with this new material and tested its oil-repelling capabilities. The results were impressive, earning a grade of 6 on the American Association of Textile Chemists and Colorists scale—matching many established PFAS coatings.

A Safer PFAS Molecule? Yes!

Interestingly, while the process involved a PFAS molecule, it was the shortest and least harmful type. As Golovin explains, the focus is on minimizing risks by sticking to shorter-chain PFAS, which are less likely to bioaccumulate.

Looking Ahead: Toward a PFAS-Free Future

As U of T researchers continue to collaborate with manufacturers to scale up and possibly commercialize this innovative coating, Golovin remains committed to finding even safer alternatives. "The ultimate goal is to create a substance that outperforms Teflon without using any PFAS at all. While we haven't reached that pinnacle yet, this progress marks a significant stride forward."

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)