Revolutionary Nanofiltration Technology Set to Transform Aluminum Production and Recycling

2025-01-07

Author: Benjamin

In a world increasingly dependent on aluminum for products ranging from everyday soda cans to high-tech applications in electronics and aerospace, it's crucial to address the environmental consequences of aluminum production. Aluminum stands as the second-most-produced metal globally, trailing only steel, and with demand projected to surge by 40% in the next decade, the need for more sustainable production methods has never been more pressing.

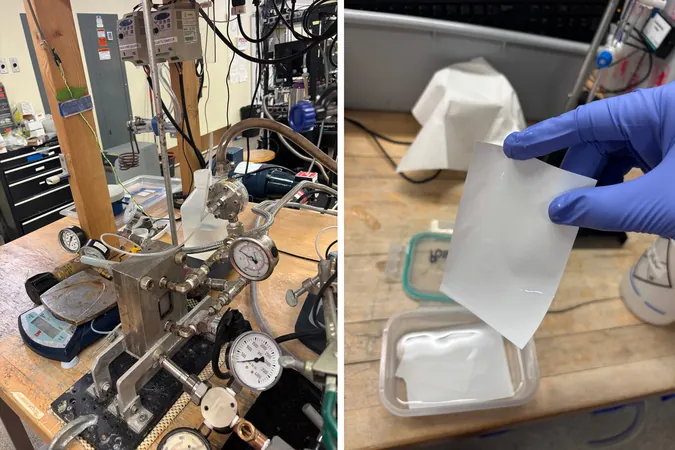

In a groundbreaking effort to mitigate the environmental impact associated with aluminum manufacturing waste, engineers from MIT have unveiled a state-of-the-art nanofiltration process. This innovative technology is designed to reclaim valuable aluminum ions that typically escape during production, allowing for their upcycling and incorporation back into the production cycle. Not only does this promise to enhance aluminum yield, but it also offers a reduction in hazardous waste generated by aluminum manufacturing facilities.

Laboratory experiments demonstrated that this advanced membrane can selectively capture over 99% of aluminum ions from solutions simulating aluminum plant waste streams. If successful at a larger scale, the implementation of this membrane technology could lead to a significant decrease in wasted aluminum and a marked improvement in the overall environmental footprint of aluminum production.

This membrane technology not only cuts down on hazardous waste but also enables a circular economy for aluminum by reducing the need for new mining. It provides a promising solution to meet rising aluminum demand while addressing critical environmental concerns.

The research team's work has led to the publication of their findings in ACS Sustainable Chemistry and Engineering, showcasing new opportunities within the metals industry for enhanced recycling methods.

A Closer Look at Aluminum Production Waste

Aluminum is produced through the extraction of bauxite ore, followed by a series of complex chemical processes. The refined product, aluminum oxide or alumina, is then subjected to electrolysis in cryolite – a molten solvent that facilitates the separation of aluminum from oxygen. However, as this process advances, the cryolite ends up saturated with impurities, necessitating its replacement after a certain threshold is reached. Alarmingly, traditional aluminum production methods result in the wastage of around 2,800 tons of aluminum annually from these byproducts.

The new research focuses on reclaiming valuable aluminum ions from cryolite waste - a largely untapped resource in aluminum production efficiency. Current technologies have not extensively explored the potential of recycling these waste products, presenting a unique opportunity for innovation within the industry.

Innovative Ion Capture Techniques

The MIT team developed this experimental membrane based on principles utilized in conventional water treatment filtrations. By leveraging the specific charge properties of ions, they adapted commercially available membrane technologies to achieve selective filtration for aluminum ions while allowing other, less positively charged ions such as sodium to pass through.

Through rigorous testing, the new membrane exhibited exceptional performance, consistently capturing an impressive 99.5% of aluminum ions even under varying pH levels and harsh chemical conditions, demonstrating its potential for widespread industrial application.

To envision its application on an industrial scale, the researchers suggest a design similar to desalination plants, utilizing long, spirally configured membranes to treat cryolite waste efficiently.

This innovation showcases how membrane technology can revolutionize the aluminum industry by upcycling aluminum and mitigating hazardous waste.

With the global demand for aluminum set to escalate, this breakthrough represents a vital stride towards fostering a sustainable future while maintaining resource efficiency in a high-demand industry. Watch this space as the aluminum world may be on the brink of a green revolution!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)