Revolutionary Metal Recycling Method Slashes Costs and Emissions – A Game Changer for the Environment!

2024-09-25

Author: Noah

In a groundbreaking development, a research team led by James Tour at Rice University has unveiled an innovative metal recycling technique that not only enhances the recovery of valuable metals from electronic waste but also minimizes the environmental footprint typically associated with metal recycling processes.

Traditional metal recycling plays a crucial role in reducing the need for mining, which often leads to significant environmental degradation, including deforestation, water pollution, and high greenhouse gas emissions. By recycling metals, we can mitigate these issues, but existing methods are often inefficient and harmful to the environment.

“Our new process significantly cuts operational costs and greenhouse gas emissions, marking a vital progression towards sustainable recycling practices,” stated Tour, who holds the T.T. and W.F. Chao Professorship in Chemistry and is a professor of materials science and nanoengineering. This groundbreaking research was featured in the prestigious journal, Nature Chemical Engineering, on September 25.

A New Era in Metal Recovery

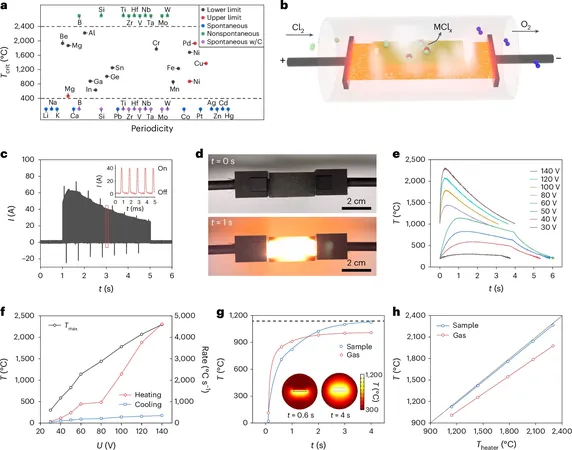

The team’s method builds on Tour’s previous work regarding waste disposal that utilized flash Joule heating (FJH). This technique involves passing an electric current through materials to rapidly heat them, transforming them into various substances. The innovative application of FJH through chlorination and carbochlorination processes allows the extraction of critical metals—such as gallium, indium, and tantalum—from electronic waste, all while avoiding the severe drawbacks of conventional recycling methods like hydrometallurgy and pyrometallurgy.

These traditional methods often consume excessive amounts of energy, generate toxic waste streams, and require large volumes of acids. Conversely, the new technique offers remarkable precision in temperature control and enables rapid separation of metals without the need for water, acids, or solvents, vastly reducing environmental peril.

Researcher Bing Deng, a former postdoc at Rice University and currently an assistant professor at Tsinghua University, expressed optimism: “We are exploring ways to adapt this revolutionary method for recovering additional critical metals from various waste streams.”

Stellar Results Revealed

The finds are not just promising; they’re impressive. The scientists achieved over 95% purity and more than 85% yield in separating tantalum from capacitors, gallium from discarded LEDs, and indium from used solar conductive films. Remarkably, this method also holds the potential for extracting lithium and rare earth elements, indicated by Shichen Xu, a postdoctoral researcher involved in the study.

“This breakthrough not only tackles the mounting issue of critical metal shortages but also presents environmental benefits, thereby economically incentivizing the global recycling industry with a much more efficient recovery process,” enthused Xu.

As the world faces increasing environmental challenges and a growing demand for critical metals, this innovative recycling method could serve as a beacon of hope—transforming how we recover valuable materials and reducing the impact on our planet. With many other researchers involved, including Jaeho Shin, Yi Cheng, and Justin Sharp, the collaborative effort showcases a commitment to sustainable technological advancement.

Stay tuned as this story unfolds, as it promises to reshape the future of metal recycling and influence sustainable practices across various industries worldwide!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)