Revolutionary Flame Aerosol System Transforms Nanoparticle Production!

2024-11-05

Author: Benjamin

Introduction

Since the dawn of civilization, fire has been a crucial tool for humans, enabling the transformation of raw materials into valuable goods. From clay pottery to the production of glass, the art of manipulating fire has been intrinsic to technological advancement. Today, this ancient technique is being reimagined through a highly sophisticated method known as flame aerosol synthesis, which enables the creation of nanoparticles essential for a variety of applications, ranging from cutting-edge inks to advanced air filters.

Challenges in Flame Aerosol Synthesis

While flame aerosol synthesis showcases remarkable efficacy, it does come with specific challenges. Researchers have long grappled with issues, such as controlling the flame dynamics, precisely manipulating the size and distribution of nanoparticles, and managing associated production costs. However, two groundbreaking studies co-led by engineers from the University at Buffalo have set out to address these limitations head-on.

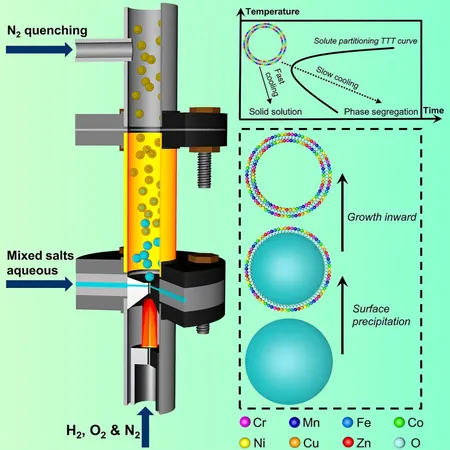

The Novel Flame Aerosol System

The latest research, published on October 30 in Nature Communications, introduces a novel flame aerosol system that the researchers have developed. This innovative apparatus is touted for its versatility, user-friendliness, and cost-effectiveness. Lead author Mark Swihart, Ph.D., a distinguished professor at the university, highlights that this is the first instance of flame aerosol technology being utilized to synthesize metal-organic frameworks (MOFs)—porous nanomaterials that hold promise in various fields, including energy, environmental science, and medicine.

Advantages of the New Method

Traditionally, MOFs have been produced through complex liquid chemical reactions, a method renowned for its precision but often criticized for being both time-consuming and costly. The flame aerosol system streamlines the process into a single, swift step, promising not only reduced production times but also significant cost savings. Although the MOFs generated through this new method exhibit lower porosity compared to their conventional counterparts, they offer unique features such as small grain sizes, short-range structures, and exceptional thermal stability, potentially paving the way for innovative materials and applications.

Scalability and Versatility

One of the system's standout advantages lies in its ability to overcome thermodynamic barriers, allowing researchers to mix diverse metal elements into a single MOF, tailored for optimal performance in catalysis, sensing, and energy storage.

Previous Research and High-Entropy Nanomaterials

In addition to the latest findings, a previous study published on August 27 in Matter showcased the flame aerosol system's ability to fabricate high-entropy ceramic nanomaterials. These nanomaterials, composed of five or more elements in roughly equal proportions, exhibit remarkable stability and versatility, making them ideal for various applications similar to those of MOFs. The researchers demonstrated the method's adaptability by successfully creating nanoparticles incorporating up to 22 elements, going on to develop an impressive carbon dioxide reduction catalyst that outperformed conventional variants in strength and durability.

Conclusion and Future Prospects

Dr. Swihart expressed his enthusiasm, stating, "The flame reactor is a scalable, one-step, and incredibly versatile way to fabricate high-entropy nanoceramics and other advanced materials." The implications of this research are monumental, potentially ushering in a new era of material science that leverages the power of flame to create well-defined nanoparticles with unparalleled properties.

Stay tuned as this innovative research will no doubt revolutionize not only industrial manufacturing processes but also the science of nanomaterials, making high-performance applications more accessible and cost-effective than ever before!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)