Revolutionary Breakthrough: Say Goodbye to Nickel and Cobalt in Lithium-Ion Batteries!

2025-07-11

Author: Jacob

A Game-Changer in Battery Technology

In an exciting development, researchers from McGill University, in collaboration with experts from the United States and South Korea, have unveiled a groundbreaking technique that promises to transform lithium-ion battery production. This new method could eliminate the reliance on costly and challenging-to-source metals like nickel and cobalt.

The Secret to High-Performance Batteries

The key to this innovation lies in a superior production method for "disordered rock-salt" (DRX) cathode particles, a revolutionary alternative for battery materials. Previously, manufacturers faced difficulties in standardizing the size and quality of DRX particles, rendering them unstable for practical use. However, this team has successfully developed a technique to create uniformly sized, high-quality particles without the need for traditional grinding or additional processing.

Jinhyuk Lee, an Assistant Professor in the Department of Mining and Materials Engineering and the study's corresponding author, stated, "Our method enables mass production of DRX cathodes with consistent quality, essential for their adoption in electric vehicles and renewable energy storage solutions."

A Leap Toward Sustainability

Their remarkable findings, published in the prestigious journal Nature Communications, pave the way for greener and more economical lithium-ion batteries. This is a critical advancement as the world shifts towards electrified transport and renewable energy options.

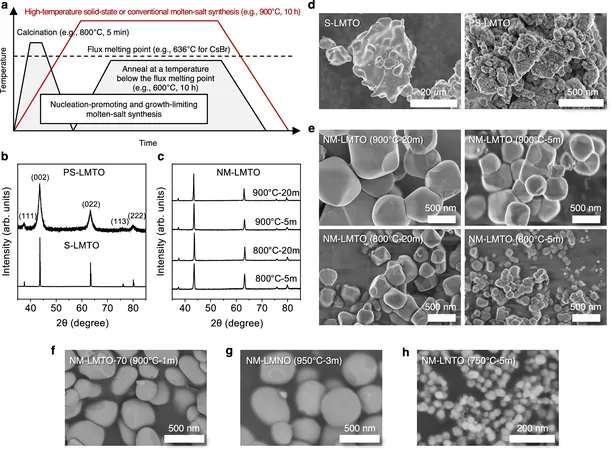

Synthesis Like Never Before

To create the DRX particles, the researchers employed a novel two-step molten salt synthesis process. This innovative approach gives them enhanced control over particle formation, significantly boosting quality and efficiency. They first promote nucleation to form small, uniform crystals and then limit their growth, resulting in battery-ready particles under 200 nanometers—ideal for maximizing lithium-ion battery performance.

Lee emphasized, "We developed the first method to directly synthesize highly crystalline, uniformly dispersed DRX single particles without the need for grinding afterward, leading to better performance and consistency in large-scale production."

Impressive Performance Metrics

In rigorous testing, these new materials showcased remarkable durability, retaining a staggering 85 percent of their capacity after 100 charge-discharge cycles—a performance that more than doubles the efficiency of DRX particles produced by older methods.

From Lab to Real-World Application

Collaborating with Stanford University's SLAC National Accelerator Laboratory and the Korea Advanced Institute of Science and Technology (KAIST), this research has garnered interest from companies like Wildcat Discovery Technologies, keen on scaling DRX technologies for commercial use. The potential for scalability and energy efficiency could overcome significant barriers to broader adoption of DRX cathodes, impacting global battery demand.

Lead author Hoda Ahmed, a Ph.D. student in McGill’s Department of Materials Engineering, remarked, "Acceptance of our work highlights both the fundamental insight and industrial potential of our method, steering the field towards scalable manufacturing."

A Bright Future for Lithium-Ion Batteries

With this innovative synthesis strategy, the team believes they have unlocked the path to next-generation lithium-ion batteries that are not only more environmentally friendly but also more cost-effective and easier to produce on a large scale.

Stay tuned, as this breakthrough could redefine the future of energy storage!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)