Engineers Break the Mold: Microscopic Machines Powered by Light

2025-09-20

Author: Sophie

For centuries, gears have been the driving force behind countless machines, but shrinking them down to microscopic sizes has posed a monumental challenge. Traditional methods using wires and magnets just couldn’t cut it. However, a groundbreaking team of scientists has cracked this conundrum by harnessing the power of light itself!

Introducing the Metamachines

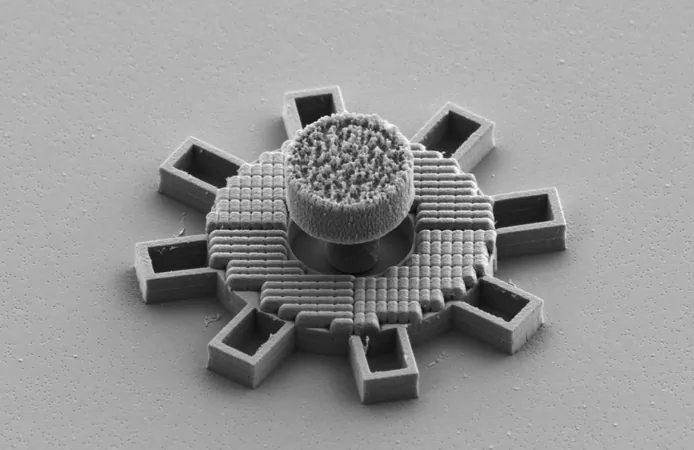

By innovatively designing surfaces that manipulate photons, researchers have crafted what they call "metamachines." These microscopic marvels can rotate, link together, and even convert rotational motion into linear movement. Gan Wang, a physicist at the University of Gothenburg and the lead researcher of this project, describes this as a "fundamentally new way of thinking about mechanics on a microscale."

The Magic of Light Manipulation

This cutting-edge technology relies on metasurfaces—thin materials with intricate patterns that interact with light. Made from silicon, these surfaces are produced using the same techniques used in creating microchips. When illuminated by a laser, these metasurfaces diffuse light in unique ways. This manipulation creates an infinitesimal torque that spins the machines at astonishing speeds.

Tiny Gears That Pack a Punch

The researchers didn't stop at creating individual gears. They also created gear trains, where one gear’s rotation powers the next. By adjusting the diameters of these gears, they could either amplify torque or increase speed, just like in larger machinery. Despite some friction challenges, these gear trains performed remarkably well in tests.

Versatile Motion with Rack-and-Pinion Systems

The team showcased a range of movements that transcended simple rotations. They demonstrated a rack-and-pinion mechanism converting rotational motion into back-and-forth movement. Altering light polarization enabled even more intricate operations—like making the components oscillate with the continuous light.

Strength in Smallness

These newly designed gears are only eight micrometers wide, comparable to a human red blood cell. They proved to be surprisingly durable, keeping operational for up to 11 hours continuously under light and withstanding months in storage. Even when their performance declined due to environmental changes, rejuvenation returned them to full function.

The Future of Microengineering

This pioneering approach is set to revolutionize microengineering. As these machines use the same techniques as semiconductor manufacturing, mass production becomes viable. Furthermore, relying on light eliminates the need for bulky components, allowing for more compact design possibilities.

Enormous Medical and Technological Implications

Given their size, these micromachines hold incredible potential for medical applications like body pumps and valves. They’re also excellent candidates for tiny sensors and optical switches in lab-on-a-chip devices. Though current designs may have limitations, the possibilities for collective machines to manipulate fluids and particles are breaking new ground.

Transforming the Future

This innovative technology stands to redefine how microscopic systems are powered and constructed. By sidestepping traditional components, engineers can embed these tiny machines in various applications, paving the way for faster, safer, and more efficient technologies in medicine, computing, and research.

Discover more of this transformative research in the journal Nature Communications!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)