Asteroid Mining: The Space Project Shaping the Future

2025-04-16

Author: Amelia

Pioneering Space Exploration with Innovative Engineering

Crushing asteroid rock into dust sounds straightforward, but doing it in the absence of gravity? That's a real challenge. Jonik Suprenant, a senior mechanical engineering student at Johns Hopkins, reflects on the hurdles faced by his team as they embarked on their ambitious "Asteroid Grinder" project.

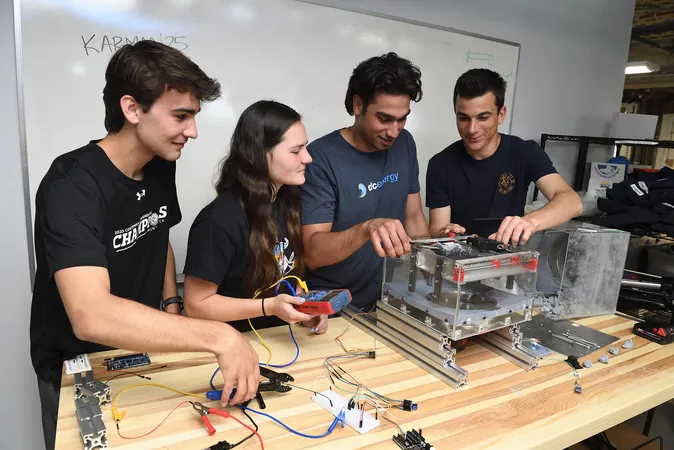

With three fellow students – Jacob Hammond, Grace Nockolds, and Zahari Stoimenov – Suprenant has been tasked with creating a prototype device designed to assist in construction efforts for deeper space exploration. Their groundbreaking project will be showcased on April 29 at the Whiting School of Engineering's Design Day, highlighting students' capabilities to transform theoretical knowledge into tangible engineering solutions.

The Challenge of Asteroid Mining

In collaboration with Karman+, a budding aerospace company focused on asteroid mining, the students face an enticing challenge: to design a compact, energy-efficient apparatus capable of grinding asteroid regolith into fine powder aboard a spacecraft. This powder has the potential to be turned into fuel for satellites, building materials, or components for solar panels—all while minimizing the costly and energy-draining process of transporting raw materials from Earth.

Once hailed as a concept of science fiction, asteroid mining is rapidly transitioning into a viable reality. Both NASA and Japan's space agency have successfully brought back samples from asteroids, signifying that commercial missions may not be far off. Karman+ is gearing up for its first mission in 2027, which aims to not just collect raw materials, but also process them in situ on the spacecraft.

Engineering a Solution for the Space Economy

"We are not just building a gadget—we're defining a process," emphasizes Nockolds, showcasing the gravity of their work. Their prototype, affectionately dubbed "Wall-E," resembles a compact cube outfitted with spinning blades and mechanical pressure systems that effectively manage asteroid rocks in a zero-gravity setting.

As the regolith flows through a unique accordion-style "gateway," it transitions into a spinning grinder reminiscent of an ice shaver. The end goal? A fine dust that can be collected, stored, and readied for future applications.

Simulating Microgravity Challenges

One of the team's standout innovations has been the creation of a three-axis rotating frame that mimics the chaotic conditions of microgravity. Rich Bauernschub, who co-leads the senior design course, noted a pivotal moment of inspiration during their presentations, emphasizing the significance of their work.

Though the device isn’t ready for flight, Karman+ anticipates it will significantly influence future asteroid missions. For the students—who juggle their academic pursuits with varsity athletics—this opportunity is more than just a project; it's a hands-on experience in real-world engineering.

Full-Circle Mentorship and Inspiration

Returning to mentor this group has been a rewarding experience for Jesse Miller, an engineer at Karman+ and Johns Hopkins alumnus. He fondly recalls his own senior design project as being pivotal to his college journey. Watching this new team tackle the complexities of asteroid mining invigorates his passion for engineering.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)